DTF transfers for companies: full-color logos, text, and detailed artwork on apparel

At Gajcom, we use DTF transfers when you need strong full-color output with crisp detail across a wide range of promotional and workwear textiles. You can choose finished printed garments (we apply the transfer to the textile) or order DTF transfers on sheets or rolls and press them in-house with your own heat press.

- Choose finished printed promotional apparel when you want ready-to-wear T-shirts, hoodies, jackets, or bags with your branding.

- We supply DTF transfers for in-house production when you have your own heat press and want to apply prints on demand.

- Your team keeps a consistent brand look even with multi-color logos, gradients, and artwork that relies on fine detail.

A) Finished printed promotional textiles using DTF transfers

If you want garments delivered ready for use, we handle the print application and recommend the right execution for your purpose (events, field teams, uniforms, gifts). DTF transfers are a strong fit when you need many colors or complex artwork without the setup of screens.

- Select T-shirts, polos, hoodies, jackets, and more when you need visible, clean corporate branding.

- This option supports both small placements (left chest) and larger prints (back), depending on how you want your brand to be seen.

- Reorders stay straightforward because the transfers are produced directly from your approved files.

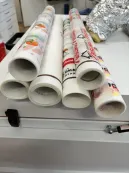

B) DTF transfers on sheets or rolls for your heat press

When you want to press in-house (internal teams, multiple locations, partners, print shops), we produce DTF transfers you apply with a suitable heat press. Transfers can be supplied on sheets or rolls, with a standard print width up to 56 cm and a minimum order of 1 running meter.

- Order transfers on sheets or rolls when you want to press per item and keep production flexible.

- A print width up to 56 cm makes it easy to gang multiple designs and improve material efficiency.

- White underbase opacity is generated in our RIP, so you don’t need to build a separate manual underbase file.

- Minimum order from 1 running meter helps with testing, prototypes, and smaller series.

What you gain with DTF transfers

DTF transfers are designed for vivid color, sharp edges, and practical application without weeding or cutting away excess material. They work well for multi-color logos, fine details, and artwork with gradients—across many common textile types.

- Get vivid colors and strong whites so artwork stands out on darker garments.

- Sharp resolution supports small text, thin elements, and detailed illustration work.

- Application requires no weeding, which can speed up production compared to some vinyl workflows.

- Lower transfer temperatures can be beneficial on more sensitive materials.

Artwork setup and sheet layout

To achieve a reliable corporate result (clean edges, correct sizing, consistent appearance), we recommend standard DTF file preparation. We print at 1:1 scale, and you keep key elements readable and technically safe.

- Send PDF for vector logos or PNG for raster artwork, always at final size (1:1) and at least 300 dpi.

- Use RGB when you want a more vibrant look, and tell us in advance if a specific shade accuracy is critical.

- Lay out designs on a sheet up to 56 cm wide and keep at least 4 mm spacing for easier cutting.

- Ultra-thin 1–2 px lines may not transfer cleanly, so we recommend thickening or simplifying them.

Quality, wear performance, and practical limits

DTF transfers are suitable for everyday use, but the final outcome depends on the textile and correct pressing (temperature, time, pressure). For new materials or in-house application, a quick test press helps lock in a repeatable process.

- For best results, a professional heat press is recommended because pressure is even and repeatable.

- Heat-sensitive textiles should be tested first to avoid shine, marks, or fabric distortion.

- For gradients, halftones, or photo-style artwork, a test print helps confirm the look on the chosen fabric.

Ordering workflow and when to combine other techniques

We run your order so the method matches your use case and quantities: DTF transfers, direct screen printing, embroidery, DTG, or sublimation (when technically suitable). You send artwork and usage details, and we recommend the execution that delivers a professional, consistent result.

- Send your artwork and intended use, and we propose the best execution and print placements for the product.

- Choose path A (we deliver finished printed textiles) or path B (we supply transfers on sheets/rolls for your press).

- Combine DTF transfers with embroidery when you want a premium stitched look in one position and full color elsewhere.

- For large runs of simple designs, direct screen printing is often the more cost-effective option per piece.

-250x250h.jpg)

-250x250h.jpg)

-250x250h.jpg)

-250x250h.jpg)

-250x250h.jpg)

-250x250h.jpg)

-220x220.png)

-250x250h.jpg)